How to choose a decent Laser Fiber burner

Fibre lasers, a new generation of devices, are characterised by high output power, excellent beam quality and a very compact design. Fibre lasers are excellent radiation sources used for a wide range of industrial applications such as macro and micro material processing, including cutting and welding. The beam of such lasers is of high quality and density and the wavelength generated is ten times shorter than that of CO2 lasers. This facilitates the integration of the laser into a cutting machine or industrial robot. These lasers are characterised by very long trouble-free operation in the harshest environments, have an extremely high reliability and laser lifetime (more than 300,000 hours MTBF), and the lifetime of the entire device is calculated at 100,000 hours MTBF, which is several times longer than that of other lasers.

Key benefits of using fibre lasers:

- high beam quality - constant for all powers

- compact size

- low cost of ownership

- stable power

- Low maintenance

- long service life

- limited heat production

- limited dispersion of the laser beam

- Quick access to the non-adjustable protective cover speeds up the production process

- easy replacement of the focusing lens

- easy nozzle replacement

- High laser resistance to damage

Fiber laser cutting costs

Fibre technology guarantees extremely low energy requirements, based on the high efficiency of the beam source, and low maintenance and operating costs due to the simplicity of the device design. Unlike CO2 lasers, the fibre laser does not require an optical path.Due to the characteristics of the generated beam and its properties, the efficiency of the fibre laser reaches a level of 25-30%, electricity consumption has been reduced by 60 - 75%, the cutting speed for selected ranges has been increased by up to three times, compared to a CO2 laser, and cutting non-ferrous metals such as copper, bronze is not a problem at all.State-of-the-art fibre laser technology is used by the world's largest manufacturers in industries such as automotive, shipbuilding, aerospace and wherever high performance with very high accuracy is required.

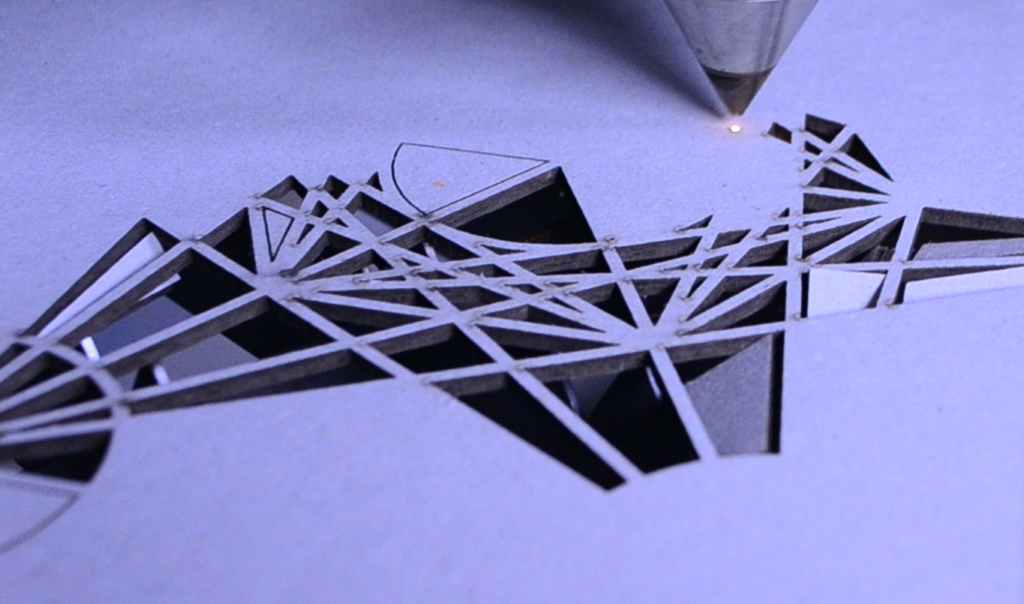

Laser Burners

Fiber laser cuts more than just steel

Disadvantages

In lasers of unknown origin the laser power is lost very quickly and after only one year they will no longer fulfil their purpose - so always buy from a reliable supplier

CNC machine manufacturing