You realise that the world is moving forward, faster, more advanced than 10 years ago. New technologies are displacing old conventional solutions. You read, you check, you research the cnc machine market and you are almost ready to upgrade your machinery. For the purchase of that one CNC machine tool that will bring you money and production independence.

Step One - Analyse your production needs

When considering the purchase of a cnc and spending hundreds of thousands of zlotys, you probably already have an idea of what you want to do on it. Nonetheless, think about it, analyse what kind of parts and assemblies you want to make on it.

You need to deconstruct your production so that the equipment you purchase is loaded to the maximum.

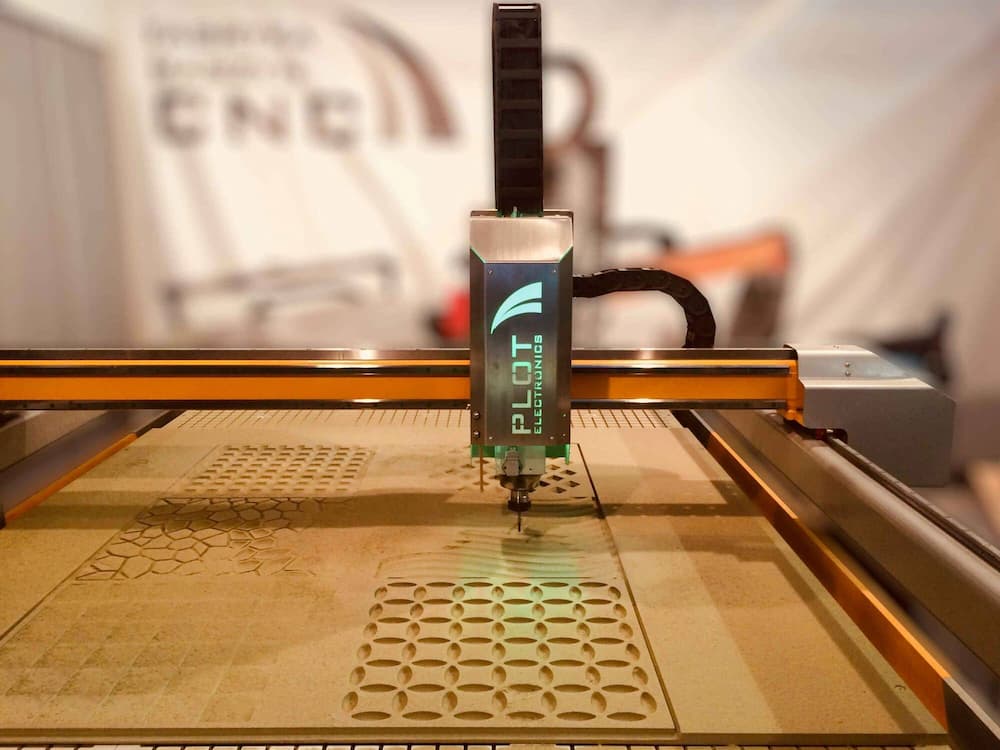

State-of-the-art CNC machine tools in addition to 2d, 3d milling, milling unitscan, with a rapid changeover to a suitable cutting unit oscillating cutting of cardboard, rubber, leather and a range of other materials).

Suitable CNC machine also has threading, creasing and scanning capabilities - which is why it is so important to know your needs. Some of the external costs can be passed on to your production thus burdening the equipment you purchase and generating further savings.

Step Two - The question you need to ask yourself - what material do I want my ideal CNC machine to work in?

If you are planning simple cutting of a wide range of furniture, advertising and building panels, the machine you have in mind does not have to bear heavy loads - unless you plan on working three shifts. Suitable alternatives for this range of materials are milling plotters with the purpose of nesting. But remember that a wider range of materials may come into play in the future. If a customer wants a top made of the increasingly fashionable HPL board (a material characterised by very high hardness), you will not be able to carry out this order with a simple plotter.

Therefore, be considerate and think ahead. Don't limit yourself to the "here and now" when choosing your first machine. The consumer market is changing, it is fluid, the tastes of consumers are diverse, board manufacturers are also introducing product innovations. You must remember that only a versatile cnc machine will allow you to be competitive in the market and will not deprive you of new orders, the implementation of product innovations. No matter how turbulent the market is for consumers and manufacturers, you will always be one step ahead. For simple cuts, pay attention to the working, idle speeds of the machines - within reason, of course. Manufacturers, cnc suppliers often offer very high working speeds that are nowhere near the actual operation of CNC machines. The safe cutting speed is 500mm/s, idle speed up to 700m/s. With higher working parameters - there is a drastic wear of cutting tools, the purchase of which is the cost of running a CNC machine. Cutters wear out quickly and break down much faster. Tools are also your side cost of production and take this into account.

Step Three - What maximum size do I want to process on my cnc, does my facility have enough space?

Yes, this question is fundamental - you may have dozens of enquiries for machining large-format moulds with an example size of 3000x6000mm but not enough space to locate the necessary cnc machine. You need to verify your plans with reality and recalculate the cost of profits and investment incurred.

Maybe you have small dimensions to work with and that's all your production is based on - then the obvious choice is to go small cnc milling and engraving machines. They are probably much cheaper than large-scale CNC machine tools - but you won't make specialised large-format moulds for composites on them.

When selecting even small milling machines, it is worth paying attention to the price and capabilities of the machine. Often machines from global manufacturers are offered at highly inflated prices with functionality similar to domestic manufacturers who offer machines at similar prices. You need to analyse the maximum dimensions of the workpieces and compare them with the location possibilities of your shop. The best way to do this is to use diagrams of the external dimensions of the CNC machines you are considering purchasing.

Before finally choosing a CNC machine - you need to understand the full cost of purchase.

Initially, you will be comparing offers from different manufacturers and the most important aspect of your choice will be the price - this will initially play a major role in the purchasing process. If you want to acquire good and reliable equipment, let's not hide - it will not be a cheap purchase. You can, also trust the importers of Chinese machines. The quality of this equipment and the functionality is equal to the price. Don't be surprised if you soon regret this purchase.

Remember if you want to do serious production you need to choose a professional CNC machine tool. A CNC machine is not an investment for one or two years, so price and constant access to spare parts and service support from the machine manufacturer or distributor are extremely important aspects.

You must include professional training or employment of a CNC operator among the incidental costs of purchasing CNC equipment. Before taking delivery of the machine, supplier manufacturers provide basic training on the machine's control system, the basics of how to operate and explant the machine. You can invest in professional training or learn from your mistakes - empirically. The best option is to learn the new equipment yourself - this is basic, then train the right people. Even if an employee wants to change jobs you will be able to continue production on your own.

The advantages of owning a CNC machine are far more numerous than the disadvantages, but there is a separate entry about that.

And one more important aspect - not every manufacturer invests in hundreds of thousands of zlotys in marketing and sales activities, some will focus a strike on the product and its functionality. Therefore, you need to set your radars against marketing 'gibberish' and sales gimmicks. The best step is to visit the manufacturer, talk to them directly and assess the capabilities of the CNC machine you are interested in.