Cnc machine technology has been accompanying industry and business for several decades.

Cnc machine tools and modern technology have undoubtedly been accompanying industry and entrepreneurship for several decades. As early as the mid-20th century, factories in the United States began to gradually introduce CNC machining technology in continuous production - to produce more, cheaper, more accurately and faster.

From the 1960s onwards, cnc technology was gradually introduced to the world market in small steps. Cnc machine tools have evolved in line with user demand. The cnc machines were becoming more advanced and tailored to individual needs - specific to particular industries.

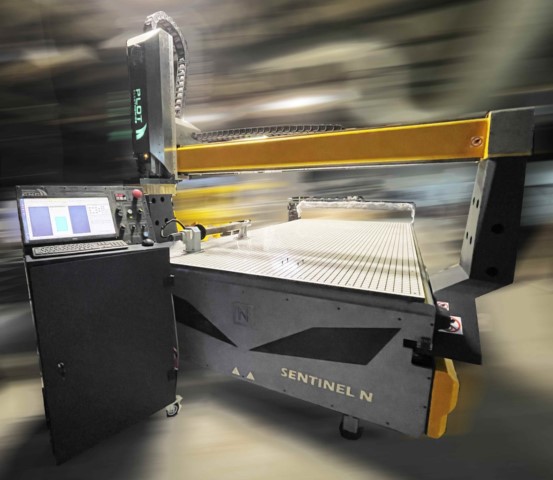

Today cnc machine is not something new, it is a 'MUST HAVE' device in most production facilities, from carpentry to aviation and heavy industry.

Hence the question is it worth investing in CNC machines?

The answer is - definitely YES.

CNC machines have been around for 20-30 years with the digital revolution of this period

Initially, entrepreneurs were afraid to invest in such advanced equipment. In Poland at that time, the digital transformation was just in its infancy. The daredevils who dared to invest in new technologies at that time - today they are probably already millionaires.

Today's market is governed by specific conditions. Economic and energy instability, fluctuations in market demand and supply, and a shortage of staff are the plight of many organisations. Having modern CNC machines allows you to re-brand your production to a completely different plant specification at any time. A perfect example was during the Covid-19 pandemic, where the economy came to a standstill in its early stages. Lucky were the owners of cnc cutters with oscillating heads. They started mass production of visors and this production was the main source of income and profit. They quickly adapted their plants to market demand and demand.

It was important to have the right idea and the right tools - the cnc machines, once set up, started a completely new production process.

Appropriate cnc machines give you production freedom independent of market conditions, allow you to develop your organisation, product, implement new concepts and production plans. The cnc machines in your plant mean savings in time, production materials, a significant reduction in labour costs compared to manual, artisanal work. In the era of the new industrial revolution of Industry 4.0, production automation is becoming a necessity. Large corporations as well as small and medium-sized entrepreneurs are aware of this. They are all increasingly willing to invest in new technologies, equipping their machine parks with modern cnc machine tools, cnc milling machines, engraving machines, cnc cutters.

Automation of production makes it possible for companies to be competitive in the market - to offer better quality goods, often at lower prices. Thanks to cnc machines, they can produce: faster, cheaper, change industrial designs, adapt to the market

Soon, owning cnc machines will be the standard for every manufacturing company. Without this equipment, production will be unprofitable.

If you need to select a CNC machine suitable for your production write to us. Our consultants will offer you the best solutions on the market.