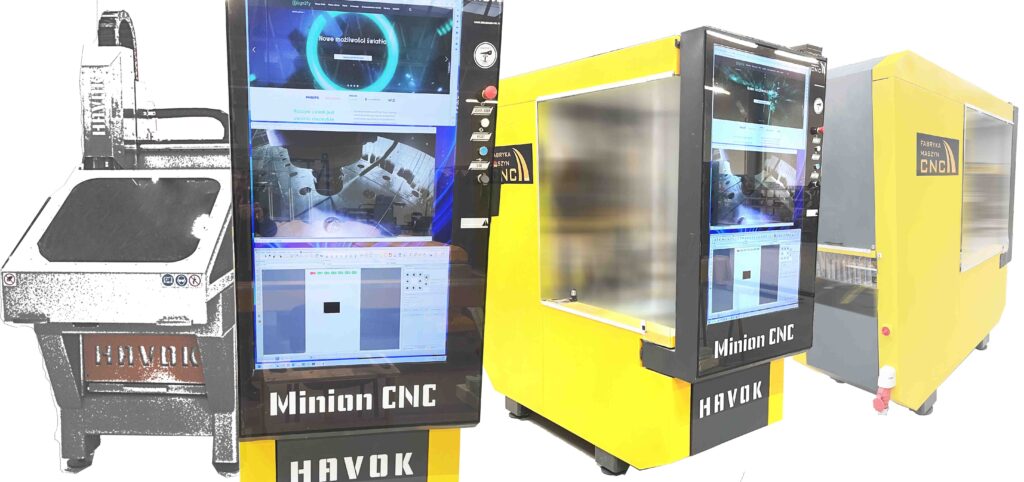

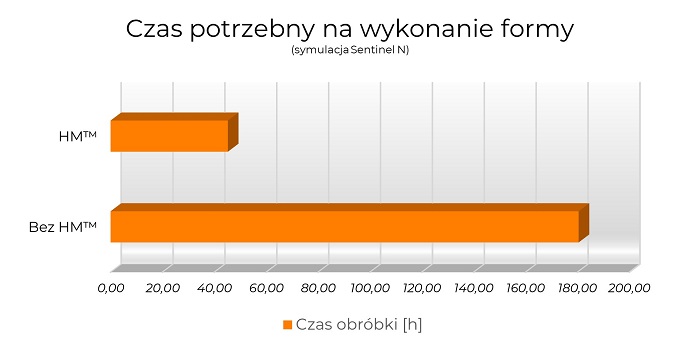

Since 2005, the CNC Machine Factory has been the only company in Europe to use a process to stiffen its structures, after which the door of the structure achieves o 1250% higher material performance compared to traditional machine tools and robots on the market. The most significant advantage of the hybridisation process is the extraction of the best characteristics of super materials. The direct result is an extraordinary stiffness, vibration damping, lightness and strength industrial robot. CNC Machine Factory's machine tools are the only ones in Europe with this innovative hybridisation technology. The entire door including the bases is flooded with a special reinforcement. The unique filling creates a monolith. As a result of laboratory tests, the resistance of the structure was found to be 12.5 times more resistant to torsion and deformation mechanical, compared to other CNC machine tools and industrial robots. This has a direct impact on the speed and quality of the workpieces being produced, enabling precise machining of materials such as steel and iron, increasing the speed of processing 'light' materials, i.e. sponge, plastics, foam. An industrial robot with this design and characteristics becomes a powerful a multi-creator machine.

Thanks to the rigidity achieved through the use of technology Hybrid Monolith™- HM™., the range of workpiece materials for machine tools and large machines is expanding.

Thanks to the lightweight constructions - production time is reduced and the service life of the mechanical system is increased.

Thanks to its properties vibration damping - greater accuracy and consistency of parameters is achieved.

Thanks to sustainability - the service life of the entire machine is increased, which makes the investment more worthwhile and the customer buys peace of mind along with the machine.

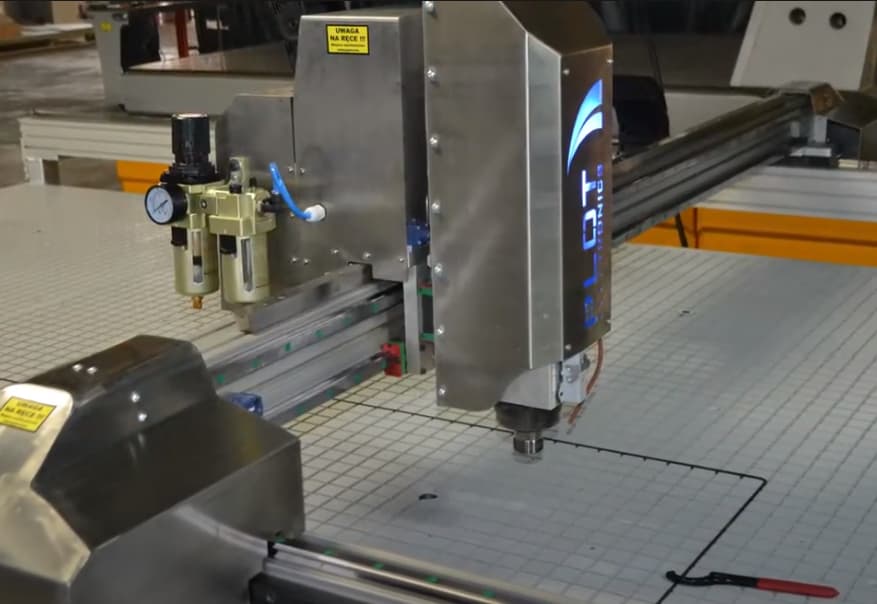

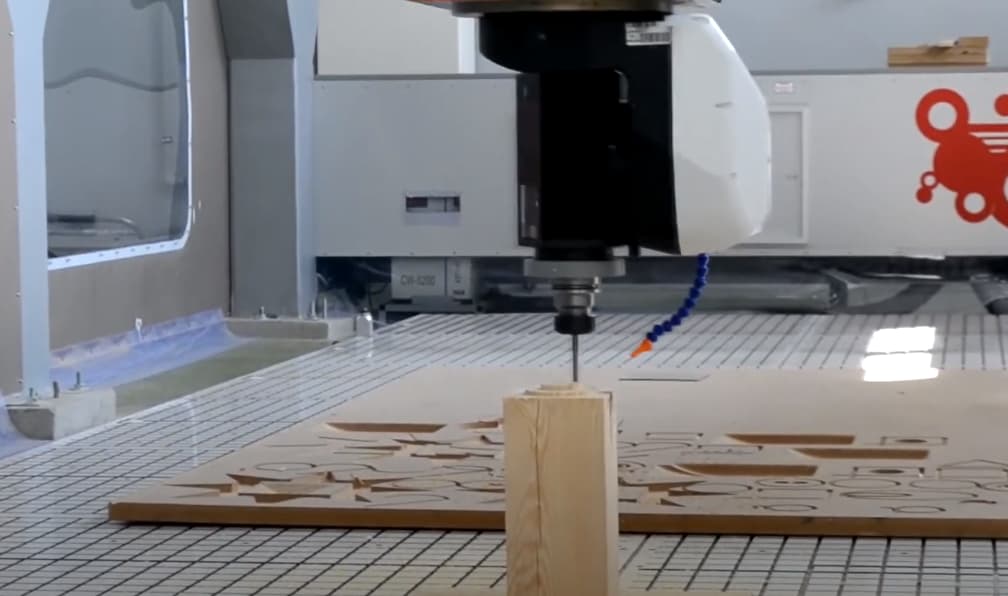

Industrial robots from our factory differ from other machines available on the market, in their idea of operation. They should be regarded as manipulators Industry 4.0 able to perform tasks depending on the head it has. The robot is able to perform many processes: Milling, Cutting, Bigging, Marking, Stamping, Punching, Stamping, Applying, Gluing, etc. The main function is milling of materials ranging from "light" materials such as sponge, polystyrene, cardboard, plastic and wood to "heavy" materials such as foam, cardboard, plastic and wood. steel, iron. Thanks to the universal properties of the machines, you can produce and manufacture on them goods hitherto unknown to you and become an important producer in a hitherto undiscovered product manufacturing process by joining the ranks of entrepreneurs Industry 4.0. Our existing customers (click here to view their realisations), thanks to industrial robots from our CNC Machine Factory, they have developed industries including the medical industry by producing medical equipment i medical prostheses, manufacturing industry (shipyards) supporting the production of the most complex and heavy steel structures. There is a reason why Sentinel is an industrial robot, a steel machine recommended by the Minister of Development.

Steel

Aluminium

Wood

Composites

Gaskets

Stone

Cartons

We have a wide range of materials at our disposal and are able to demonstrate the work of the machine on the material of the customer's choice on request.

We have a wide range of materials at our disposal and are able to demonstrate the work of the machine on the material of the customer's choice on request.

Another unique feature of our machines is multitude of tools possible to use in the machining process. This ranges from simple and typical tools used in industrial robots and CNC machines, i.e. drills, various types of milling cutters to heavy and complex machining heads, 4th axis on a spindle, angle heads, oscillating heads, cutting heads, and creasing heads. We are the author and manufacturer of oscillating head i creeping (catalogue of available heads is available in our CNC shop) and our many years of experience in the industry enable us to produce them ensuring best performance of all those available on the market. The components used eliminate mechanical problems guaranteeing long and efficient operation even under the heaviest loads. The tool changing process is also an important component of the industrial robot. Thanks to the use of a specially designed tool magazine and fast passes of the machine, the time required to change the tool is reduced to minimum providing peace and comfort operator. All heads are compatible with our tool stock so weight, type, type and size of tool is not an issue when robotic tool changing.

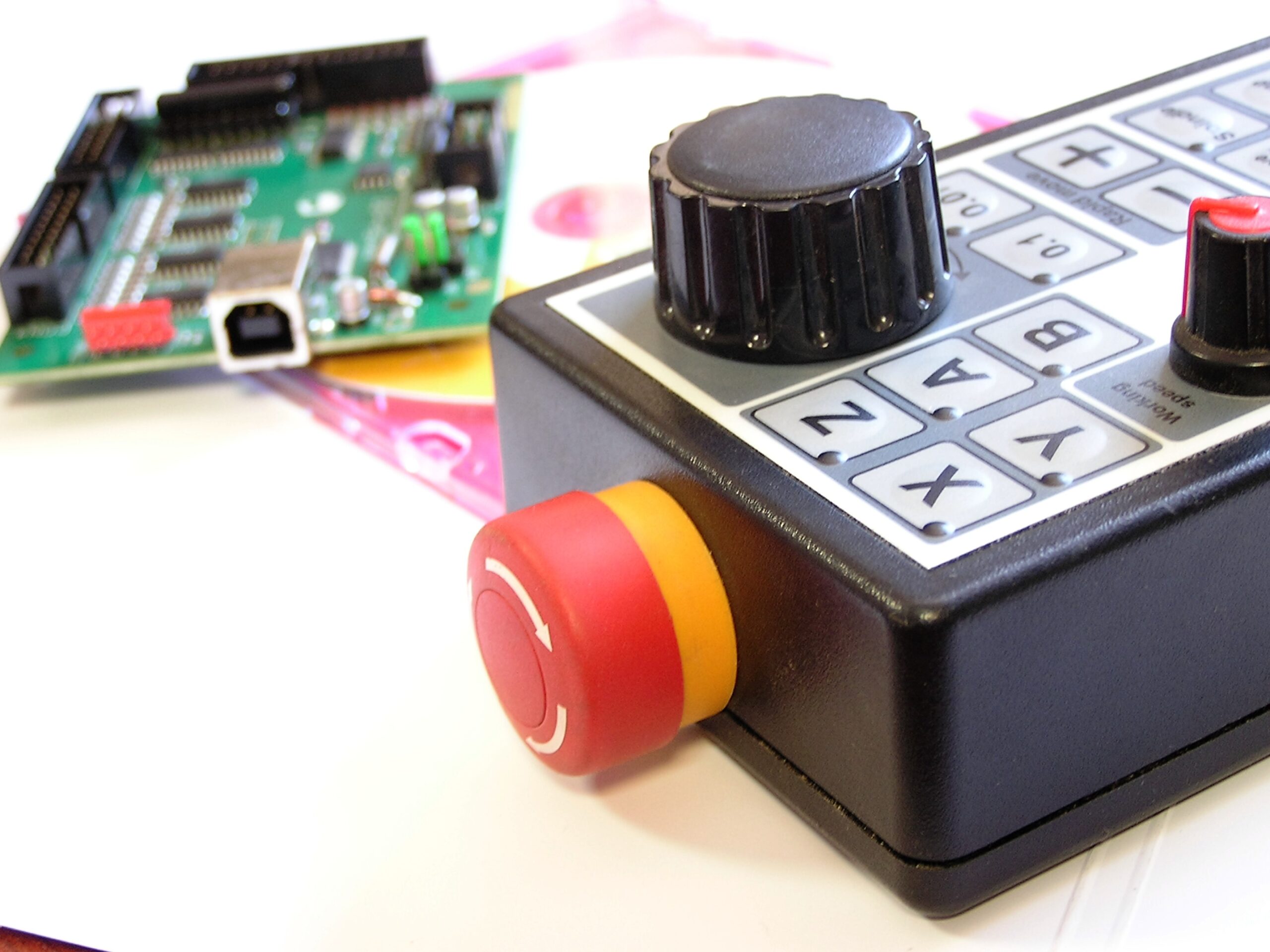

CNC Machine Factory equips every industrial robot with a high-tech control system, which is the heart of the machine. It is responsible for communication between the user's interactions and the machine, generating the timing and direction signals of the stepper motors. The more technologically advanced the controller is, the more working with the machine is more precise, faster and minimises human error. The controllers we implement in CNC machines are unrivalled in the ranks of CNC machines and extend the capabilities of any machine tool operator. Thanks to a proprietary solution - connecting the control system with servo drives via a communication protocol PLINK Ethernet has succeeded in increasing the transmission speed between the interpolator and the servo drive to a cycle of 50 μs, which translates into a high sampling rate of the controllers (position fixes) not worse than 50μs (20kHz). The use of numerous technological solutions allows the controller to support 5-axis control with dual drive in the X2 or Y2 axis.

The operation and control of industrial machine tools is possible from a control panel located directly on the machine or by using a wired remote control module called the Sentinel. To ensure operator comfort and flexibility, each machine is equipped with a wireless communication system -. WiFi. This makes it possible to modern and innovative control method involving remote operation of the machine by using a laptop, tablet, smartphone or external computer. For this purpose, we provide special software for these devices, which allows you to operate and maintain control of the machine from anywhere in the world (internet access required). Thanks to a series of training courses at our company headquarters in the Masuria region, any beginner can become an operator by learning basic as well as advanced machining techniques. We make available training materials allow you to further develop your CNC knowledge and implement new ideas in the industrial market.

The measuring systems in the industrial robots manufactured by the CNC Machine Factory are precise and demanding sensors, whose accuracy, the accuracy of the information as well as the method and speed of data transmission to the control unit determine the the accuracy of the machine and testifies to its of the highest quality among the machines available on the CNC market. Thanks to the use of proprietary technology connection of the sensors to the control system, they are able to transmit measurements with an accuracy of 0.01mm - This includes measuring processes such as tool length, material thickness, speed, distance travelled, angle of rotation and zero point. Thanks to the use of such precise measuring elements in the machine, we are able to ensure the highest accuracy when processing any type of material - from sponge to steel. Industry 4.0 is a revolution in industrial robotisation and we are ready for it.

When creating industrial robots, we are guided above all by the assurance of speed of operation and trouble-free performance control software by implementing solutions Industry 4.0. We only use proven components that will not let the machine operator down even in the most demanding moments of interaction with the machine. Thanks to the use of the latest generation of processors and super-fast M.2 SSD drives, we are able to guarantee the speed and reliability of the control unit. All the devices that we attach to the machines are controlled by a single programme which makes the The Sentinel highly intuitive industrial robot. Graphical interaction with the user is made possible by the software cncGraF offering min:

Intelligent correction of material height by scanning the work surface,

Integrated CAD module,

Path optimisation with a smoothness function increasing the speed of curved journeys,

4 and 5 axle operation,

Complete 2D/3D visualisation of the workpiece,

Correction tool with graphic preview,

Integrated G-Code text editor,

Z2 rotary axis support and much more.

AI algorithms automatically adjust speeds to the curve ensuring smooth running of the machine and reducing "jerking" with erroneous data. The control system, thanks to its precision and such low latency (communication PLINK) is one of the best, ensuring reliable operation and the latest firmware updates ensure operator safety and peace of mind.