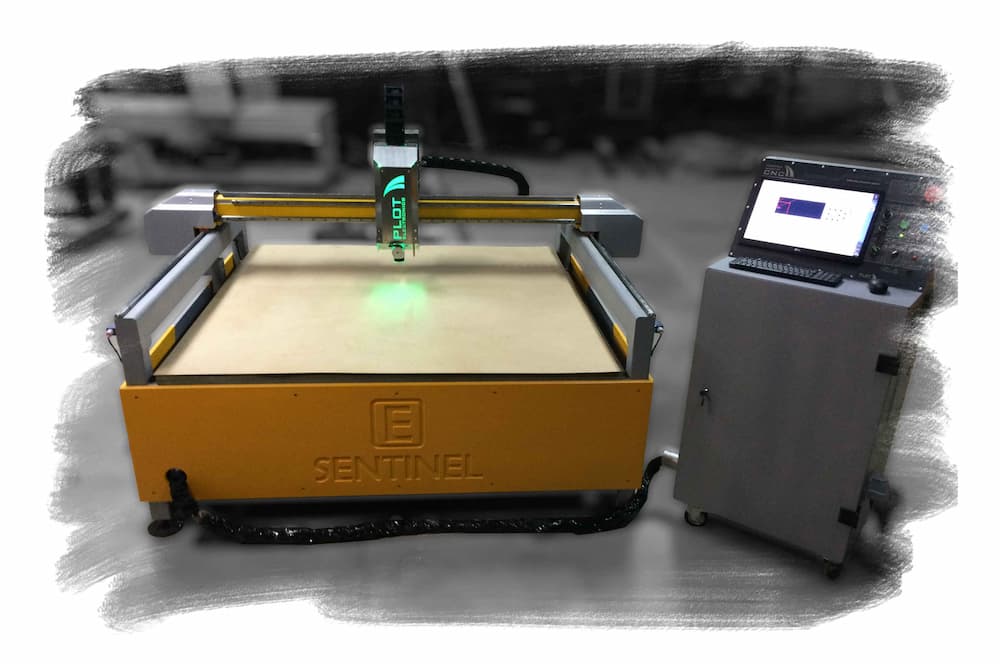

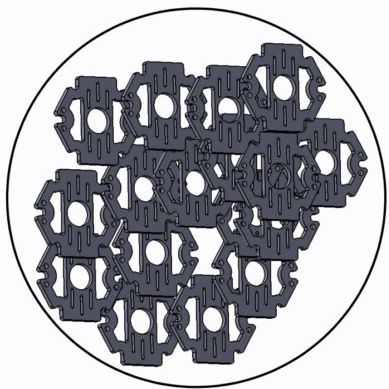

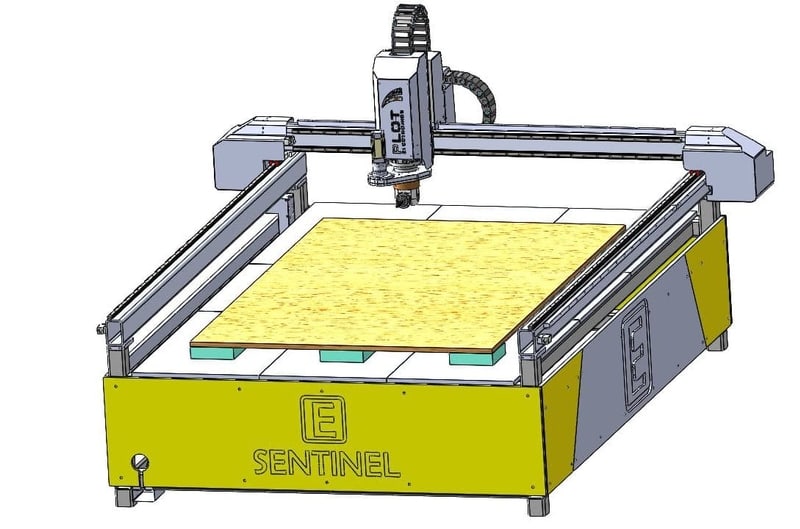

Series milling plotters SENTINEL E are ideal for fast nesting - cutting materials. Thanks to the unique - light but rigid design, the machine achieves very fast idling and machining passes. This guarantees fast and accurate work. This feature is particularly appreciated in various cutting, engraving and drilling operations and wherever time is of the essence.