CNC machine or toy?

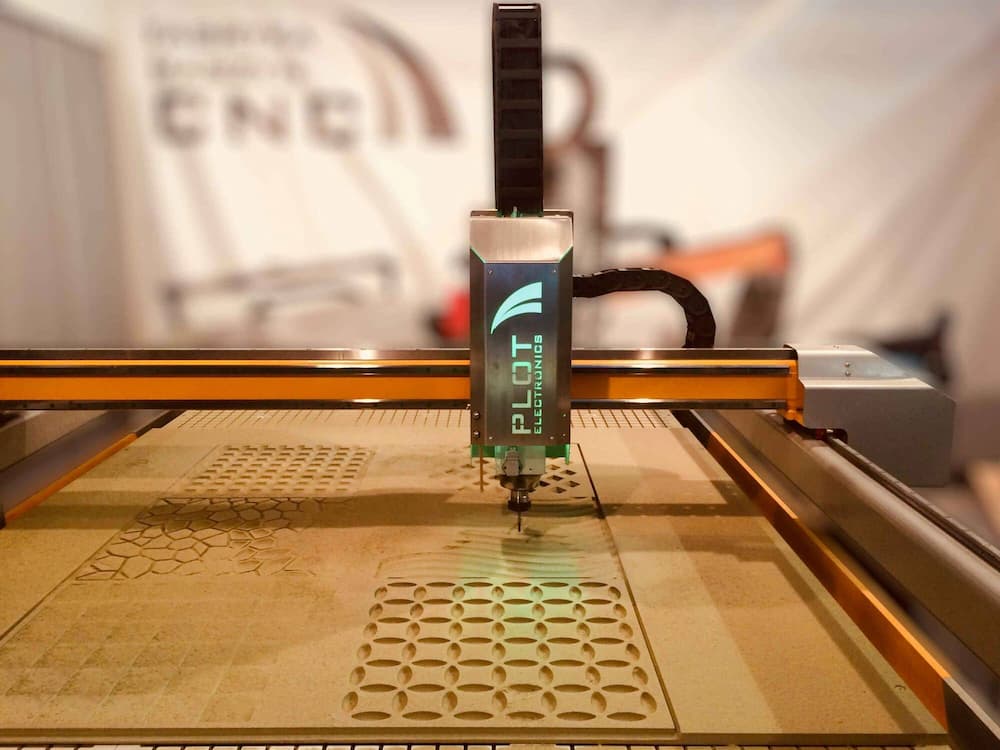

How do you tell the difference between a real CNC machine and a toy? This is a question many novice customers ask themselves, unaware of the differences between products on the market. Plot Electronics, with more than 20 years of experience in building and constructing CNC machines, can help to solve this dilemma. Over the years, we have learned that you cannot skimp on high-quality components if you want to ensure the reliability and precision of your equipment.

Components used: Key to sustainability

Initially, any manufacturer may find it difficult to choose the right parts, but our experience has taught us that saving on quality ends up costing more in the future. The CNC machines we build are made for production, not play. You will find many machines on the market that look professional, but in reality are just 'toys' - cheap, not very robust and prone to failure.

Traps of cheaper substitutes

Typically, imported machines that mimic professional equipment are priced low - 10% to 20% worth of machines from established manufacturers. Instead, as often happens, many sellers bump their price up to 500%, presenting them as premium products. Therefore, before buying, compare the product carefully on different platforms (e.g. Aliexpress), paying attention to key mechanical components such as the running gates.

These low-budget machines are usually based on outdated technologies, such as stepper motor drives, which have been falling out of the industry for two decades. If such equipment goes into production, you will quickly see a drop in accuracy and, consequently, a reduction in profitability.

Conversions versus real opportunities

Some companies are trying to upgrade cheaper machines by adapting them to more demanding tasks. While this may initially seem like a good option, these machines have a limited lifespan and are not suitable for reconditioning. They simply cannot withstand the intense production load.

How do you tell the difference between a CNC machine and a toy?

One test that can be carried out is the simulation of a collision. In professional CNC machines, even at full speed, a collision should not permanently damage the mechanics. On low-cost counterparts, such a situation could lead to permanent damage.

Brand trust: Is it always justified?

Many companies choose machines on the basis of the manufacturer's reputation, without paying attention to current service or warranty conditions. Meanwhile, changes in the market can affect the quality of service or after-sales service. Therefore, it is worthwhile to carefully examine the warranty conditions and make sure that the service will not take weeks in case of problems.

Summary

When choosing a CNC machine, it is useful to know the differences between the components used, which affects its durability and capabilities. Good quality components, although more expensive at the outset, can result in significant savings in the long term, minimising the risk of downtime and costly repairs.

Determine what parts it is made of

Digital servo drives - there are many classes of these and so-called pseudo solutions like stepper motor with encoder (ezi-servo) - this is the main difference. On Professional machines, these are usually AC servo drives , which are capable of taking on multiples (3-10) of overloads during operation and when idling. AC servo drives are very expensive and actually represent about 40 % of the value of the machine. The efficiency is a multiple of machine work done on stepper drives or ezi-servo - the 3D work itself takes 10-20 times faster and the results are noticeable in terms of quality to the naked eye. In the super professional series, the servo drives in the machines produced have 800% overload capacity, which in the case of cheaper machines is at the level of 300%, which is 2.6 times higher, giving higher acceleration and speed of execution of details in comparison with cheaper solutions, and 8-20 times higher than in the case of machines on constant torque stepper motors, which are classified as toy machines. Also important are the speed of response to deformation or the filters and algorithms used to control the drive, such as harmonic filters or pendulum filters. The use of advanced capabilities in terms of speed performance is essential. Modern servo drives have a balance between algorithm and direct drive response to deformation. Getting rid of the algorithms and simplifying the block responses increases speed but will not increase precision, nor will it allow correct operation for changes in the nature of the operation. Machine designs have internal stresses that can cause vibratory deformations, which are dampened by the possibility contained in algorithms that defy the laws of physics and are able to stop the accelerated mass without overshoot and visible vibrations on the workpiece. It is therefore not true that the fastest reading and response of the control system to the deformation is the best choice. It does not take into account the quality parameter of this change. There is a fast response, but is it correct ?

Linear drives, which are heavily advertised as direct drives, are also used. The drives differ in performance by about two to three times being faster than industrial machines, but they also have their disadvantages. An important parameter is energy density, which is a direct result of the components used, including rare earth magnets. This technology has been known for many years but is only just being implemented in cnc milling machines. Previously, it was used in machines such as lasers or plasma cutting machines. The components used in their manufacture have an impact on the power of a given motor and its size and weight, which is important during fast feeds. In milling work, the level of capability is only satisfactory in machines with small working areas due to the large winding cross-sections and the large currents flowing through them giving power over small distances.

In large-scale milling machines, the use of linear drives does not yet have a sufficient level of power to maintain the milling position.

In order to be able to use servo drives in the machine, it is necessary to machine frames with high accuracy, which are machined to an accuracy of +/-0.01 mm, and such are also the linear guidance components of the carriages in class H and P. In non-professional machines, the level of workmanship or deformation during operation is much greater and reaches up to 1.2 mm. For the furniture industry, these values are acceptable, but pose a problem for the service life of such a construction. The given changes lose their deformation resistance properties and become bent, changing their geometry after time, or do not hold on the workpiece, deteriorating their properties with the time of the cnc machine. Machined frames may be in poorer tolerance and if the frame has larger deviations a linear guide is used in a deteriorated class - designed for sliding doors etc. The carriage class is 0.3mm, but there are usually 4 and the errors add up - this allows the machines to run because the clearances are large enough to cover the mechanical errors. The errors are only apparent when the cutting load is greater than the weight of the guide body - then you know what the machine is worth. Plot Electronics has fine-tuned the machining process and makes devices with a very high accuracy class of 0.01 mm as standard on 4 metres. Higher accuracies are possible, but time is of the essence in terms of economy. The class of components used is also selected according to machining accuracy. The design of the machine has a great influence on the quality of the workpieces, the possibility of using large tools and the service life of the tools and the machine as a whole. Welded constructions are subjected to internal forces that affect the stability and performance of the CNC machine. This process is covered by company secret and patent, but in many cases temperature, chemical or vibration annealing is used. If you do not have an annealed print, then your design has not been in a furnace and this can easily be checked by looking inside the profile. Vibratory methods have no visible signs, but you can easily hear the structure, chemical methods have similar effects to annealing, and there is also an ageing method where the structure is subjected to daily life and rests.

Many spindle suppliers are found on the CNC machine market and it is difficult to judge directly which ones are in a class of their own and which ones are just for fun. Depending on the needs, spindles are selected according to the operating characteristics supplied with the spindle, which guarantees stable operation after proper parameterisation by a controller called an inverter. Plot Electronics uses spindles from HSD, Hiteco and other companies whose products are characterised by exceptional quality and durability. On the market of CNC machines, you can find equivalents of HSP and water-cooled spindles used in the amateur class, commonly called Wet Chinese spindles - this is how spindles from China are described. Their power in comparison tables has nothing to do with reality - it is the power consumed and not the effective power on the shaft. The power comparison therefore makes little sense because there is no guarantee of stability.

The advantage of the professional spindles used is their non-linear working characteristic, which has a peak in power at the average value of the maximum rotational speed, giving the possibility to work in a larger range of rated speeds. Plot Electronics takes advantage of this advantage by enabling it to work at low cutting speeds and, as a result, allowing the user to work with the parameters envisaged for the process of cutting steel materials at 800-3000 rpm with a spindle with a maximum speed of 24000 rpm, which enables the user to work with many different types of materials with an advantage over other solutions.

Also of significance is the spindle control itself, which is implemented through Automation and a device called an inverter, which features inverter operation pumping energy into the motor equal to the energy consumed. This saving keeps the motor at optimum rated conditions for the load. Such a spindle is therefore utilised to the maximum and unused energy does not occur and is not converted into heat. This saves energy and offers tremendous opportunities to precisely control the torque spindle speed, but also to control the cutting motion. Spindle frequencies range from 200 to 1,000 Khz, which makes it impossible to use vector operation algorithms up to 300 Hz, whose efficiency is 1.4 times higher than scalar control; for higher frequencies, proprietary algorithms are used, the programming of which can only be performed by the manufacturer's service.

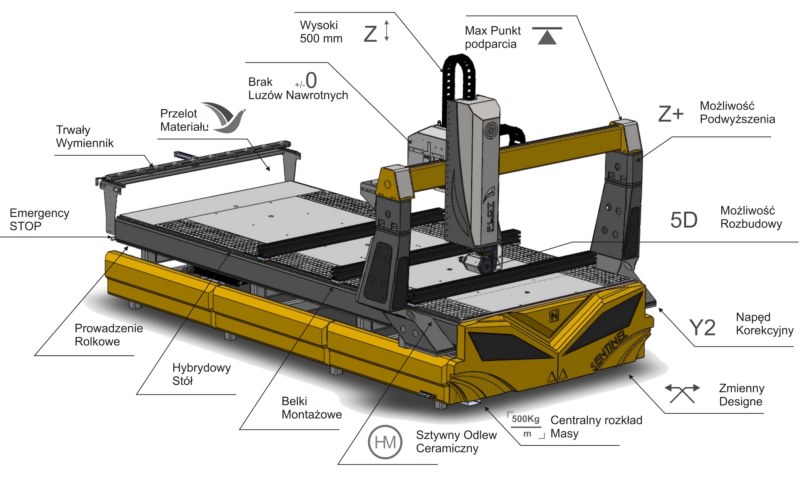

Drive is by means of planetary gears and helical slats, also in the Z axis, which is unique among the competition. This solution protects against collisions - possible program errors - inattention, etc. On Plot Electronics machines, nothing bad will happen during such incidents - the machine will shut down. The machine is protected against operator errors. After switching off, switching on again and performing a reference run, the machine fully returns to its original settings. The machines are designed for such eventualities thanks to years of experience. The use of helical drive in Z-axis mechanics involves the use of planetary gear elements and expensive motors with integrated brakes. The solution used by Plot Electronics is more expensive but reliable and durable.

Competing machines use ball screws, the collision of which causes damage to the drive, usually to couplings and mechanical components, and to balance the weight, Z-axis booster cylinders are used, which in terms of safety and system complexity is an outdated and unreliable solution.

The Y-drive system operates independently, allowing the right-angle correction system to function - the loads during operation for extreme dimensions are different for both drives - the relevant algorithms take care of synchronisation and the angle system always positions the machine precisely during reference.

The parameters and accuracy classes in which the components are manufactured and installed are important, and this is not readily apparent at first glance.

In toothed strips, the grades used start from T6. For many manufacturers, this is not important and they use cheaper substitutes, the quality effects of which are felt on the workpiece but also in terms of durability. If the quality is poor, there are visible signs of wear in the form of scuffing on the edges of the helical strips, which causes deformation of the scale and the machine does not keep to the parameters.

The mechanics of cnc machine building are proprietary and have an advantage over competing solutions. The X-drive slides are mounted at the top and bottom of the beam, which enables the transfer of greater forces due to the larger spacing than in competing solutions, this results in smaller cross-sections of the running beams in the machines than in competing solutions, but the axial spacing is larger, which enables the transfer of greater cutting forces, in addition the slides do not need folding guards because there is no concern about dust on the slide because from above and below the chips and dust are easily cleaned by the ball carriage scrapers. In competing solutions, the guides are bolted to the side of the beam, which results in smaller spacing and the need for larger cross-sections of running beams in addition to the folding covers, which make it difficult to reach the guides for the operator checks and cleaning that are required. Mounting Y drive guides on the machine structure is also a mistake, but is used by many machine manufacturers avoiding the impact of machining errors in the structure on machine errors. The machining of the planes on the sides of the profiles is apparent and is intended to roughen the machining so that only the tracks can be seated. The expansion of the steel in such structures causes it to push against the side walls of the profiles of which the machine is made. This causes changes in the concavity or convexity of the profile to which the guideways are attached, which in turn push against the bogies and these widen the spacing between the supports of the beam. In such cases, the 4-row carriages support the entire load of the beam on only 2 rows, limiting the service life of the carriage and resulting in relatively faster wear of the carriages. An additional problem with this design is the settling of excavated material and dust on the bearing sill, which necessitates the use of covers. One important aspect is the fact that the guideways stick to the bases, otherwise the guideways will not withstand the pressure of the weight and will fall on the bolt until it is blocked against the side edge of the bolt. The construction of the kinematics is not wrong, but regular maintenance and almost daily lubrication must be remembered.

In designs with bottom-mounted tracks, there are no mechanical faults and the tracks are not stressed and are naturally protected from the ingress of dust or chips. Cleanliness is easier to maintain in such constructions and the service life of the bogies is more than 10 years with frequent lubrication.

Clearances in CNC machines appear after about 2 years of operation and must be corrected by tightening the special screws that push the gears against the gear rails.

The machines offered by Plot Electronics use a proprietary solution that automatically applies pressure to the drive to prevent backlash, giving ideal operating characteristics for years to come while protecting the entire precision mechanics of the machine from operator error or collision.

In addition to the adjustment function, the proprietary solution absorbs most of the vibration and oscillation of the mechanics during the cutting process, which extends the service life of the entire mechanics several times and gives the possibility to work with unbalanced or special tools.

Vacuum clamping is moving into the standard and is a popular clamping solution for boards and components with a sizable surface area. There are problems with clamping smaller components, which Plot Electronics has tackled by applying a proprietary solution and developing clamping methods in the form of vacuum antiforms. In addition, the vacuum pumps used are developed for Plot Electronics and are characterised by higher efficiency and lower energy consumption based on the use of pump speed control by inverters and programming in sinus-vector algorithms. This solution controls the operation of the motor using a vector rather than a scalar measure, resulting in an efficiency that is 1.4 times higher than nominal, which is due to the vector operation of the motor. In addition, the pump model used is in 60hz operation which increases the pump capacity by approximately 20% The use of motor control for vacuum pumps on cnc equipment is not found in competing companies.

In the case of Plot Electronics, the machine gantry and chassis beams are reinforced crosswise by interlocking bars (ribs). This is a very labour-intensive operation, but according to our research (and external studies) increases the stiffness of the entire system by about 7-8 times that of machines made on normal profiles. On new machines, the system is additionally flooded with HM+ compound (proprietary solution), which increases rigidity by about 12.5 times. Some CNC machines also use compartmentalised reinforcement and polymer concrete flooding, but in this case, after about 10 years, corrosion and weight loss occur, leading to loosening of the filling material and the creation of a cavity around it.

Based on 20 years of experience and many different cases in thousands of CNC Machines production, I would certainly recommend to buy professional machine tools from Sentinel N series. All owners of these cnc machines have succeeded. Feel free to contact us.

The CNC machine market is rich in all kinds of solutions and at first glance we do not know how to choose the right cnc machine for us. The only thing we consider is the size of the machine's working area, ignoring all other important factors. Often, the only reason to choose is the confidence that the machine's salesman has inspired in us, often using marketing tricks and sales manipulation to achieve their goal. Often they are brilliantly marketing-trained salesmen who say what you want to hear. When choosing the right cnc machine, use common sense above all and follow some of the rules listed below.

Determine your needs

First of all, you need to establish your needs and this guide will help you make the right selection of the cnc machines available on the market.

If you run a small business in carpentry and contract out work such as cutting formats, then it is imperative that you purchase a CNC machine and start earning your keep rather than giving away the money you earn. The services are costly and often lock you out of the final profit in terms of time and quality.

Determine the purchase budget

If you have already made the right decision then you initially have to face the financing of your planned purchase. You usually determine your budget and, like many, fall into the first trap. You look for CNC machines available on the market and follow the principle of buying what you can afford. You look on the Internet, type in the keyword "milling plotter" and a lot of offers come up, and the prices that come up suggest prices of around 50,000 and you determine your budget based on this.

If you did then you have just fallen into a trap.

Why?

Because no major manufacturer puts its machines on sale portals. Usually for purely economic and practical reasons.

The manufacturer of the machine has incurred a huge expense to make such a machine and the level of earnings is set in the range of 5 to 25% which, given the huge margins of up to 10 % in value for brokering, is unprofitable. This is in contrast to goods imported for volume.

This is why most of the low-budget machines are visible online and create confusion among the real production cnc machines, which range in price from 200 to even 900,000. Yes, this is a considerable sum, but it is also a production machine, not a training toy.

You can't build a real business based on toy solutions, but not everyone has such ambitions and for some of the manufacturers such equipment is sufficient. If you had a format saw and edge banding machine, buying a plotter is a big technological leap for most, even in its simplest form. One hard maths leaves no illusions.

- The efficiency of imported machinery is 20 times lower.

It's like having 20 friendly companies folding into 1 professional one.

This is a seemingly very complex subject. If you decide to buy a machine and take out a lease or a loan, the machine will be paid back after a maximum of 5 years, usually after 1.5 years. If you want to use EU subsidies to buy such equipment, the whole procedure usually involves a year or so of wrangling with officials, applying for certificates and spending money on intermediary offices and paying any other fees for the project. Therefore, you need to know what you will face and plan well.

They are not bad in themselves, but there are a lot of problems associated with them, which only come out during or at the end of the whole procedure, because the companies will not always tell you everything. Of the most important things you have to remember is that on machines purchased with EU funds costs are not deducted from income and the funds received are net, but you have to pay the amount with VAT, which you will recover, but only after the whole transaction and in addition only after a few months, it is such a small credit to you. Then there is the risk you run in the whole procedure related to the tender you are obliged to advertise in the Competitive Database. Usually, the companies you have previously estimated the price of the equipment you were interested in and included in your application win. This used to be the case, but now the new regulations dictate that tenders should only be advertised through the Competitive Database, which involves choosing the cheapest device with certain parameters. And everything would be ok if there were dishonest companies that automatically sign up to meet the conditions, but this is usually not the case. Companies come forward that assume you will choose their cheapest offer because you have no choice. By doing this, you will expose yourself to buying a device that is usually the cheapest and simplest device that does not meet any of the parameters you needed and the bidder has guaranteed. This is the trap that many inexperienced companies fall into, who have not included procedures in their tenders such as : a site visit to the manufacturer, tests of the device, etc.... where the bidder is forced to accept you and show you his solution and which you have influence over. Otherwise, they will offer you something similar that lacks functionality or even basic parameters and unfortunately you will be forced to purchase such a device. Once you have received your order and the shortcomings are discovered, you will only be left with a court case to recover the money and return the goods, which can be a multi-year process in which you will have to prove that the device is different from what the supplier described. So be careful and entrust the purchasing procedure to an experienced company. There are many more twists and turns to meet, but it is worth it if you are sensible and take into account the turbulent times, volatile device prices and long waiting times and inflation. It is the funds you raise that must be greater than the price you offered. Don't leave everything to the last minute. Tenders can be cancelled, but you must give yourself time to issue a new one with a proper declaration preventing companies offering equipment similar in name only and not meeting the conditions from taking part.

This is an important consideration in determining your needs, which you take into account when choosing a machine for your needs. It is usually high in professional machines and low in imported machines. In fact, toy machines are extremely low in price and reach up to 5 % of the value of CNC machines from professional companies, but traders increase these prices to the value of 51 % of the price of the others so as to avoid differences in the phrase 'abnormally low price' used in EU and purchasing agreements. Check the prices of similar machines on well-known portals, you will find the machine offered there in other colours or housings. Keep an eye out and do not be fooled.

Based on 20 years of experience and many different cases in thousands of CNC Machines production, I would certainly recommend to buy professional machine tools from Sentinel N series. All owners of these cnc machines have succeeded. Feel free to contact us.

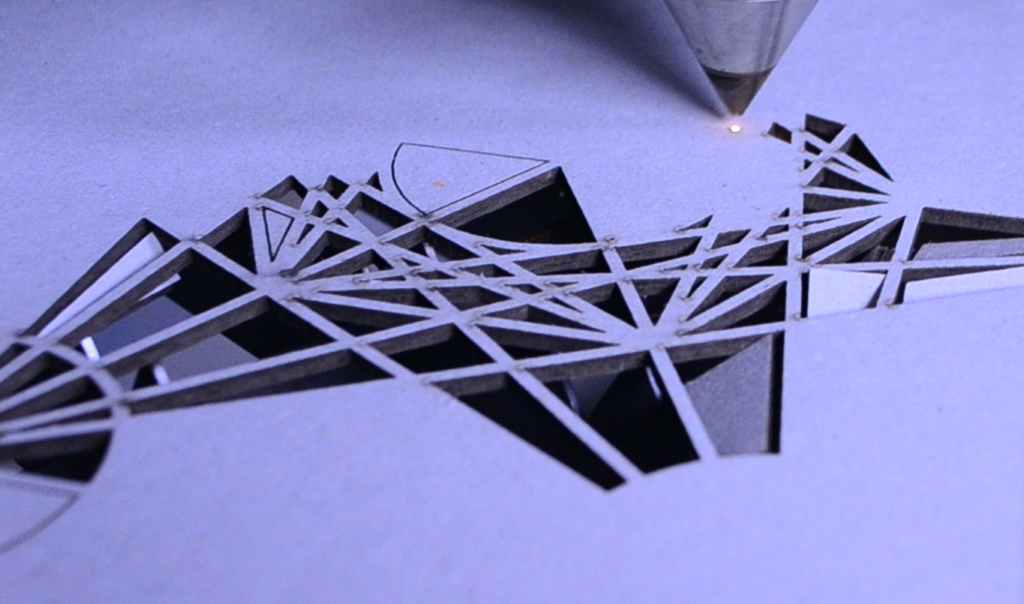

How to choose a decent Laser Fiber burner

Fibre lasers, a new generation of devices, are characterised by high output power, excellent beam quality and a very compact design. Fibre lasers are excellent radiation sources used for a wide range of industrial applications such as macro and micro material processing, including cutting and welding. The beam of such lasers is of high quality and density and the wavelength generated is ten times shorter than that of CO2 lasers. This facilitates the integration of the laser into a cutting machine or industrial robot. These lasers are characterised by very long trouble-free operation in the harshest environments, have an extremely high reliability and laser lifetime (more than 300,000 hours MTBF), and the lifetime of the entire device is calculated at 100,000 hours MTBF, which is several times longer than that of other lasers.

- high beam quality - constant for all powers

- compact size

- low cost of ownership

- stable power

- Low maintenance

- long service life

- limited heat production

- limited dispersion of the laser beam

- Quick access to the non-adjustable protective cover speeds up the production process

- easy replacement of the focusing lens

- easy nozzle replacement

- High laser resistance to damage

Fibre technology guarantees extremely low energy requirements, based on the high efficiency of the beam source, and low maintenance and operating costs due to the simplicity of the device design. Unlike CO2 lasers, the fibre laser does not require an optical path.Due to the characteristics of the generated beam and its properties, the efficiency of the fibre laser reaches a level of 25-30%, electricity consumption has been reduced by 60 - 75%, the cutting speed for selected ranges has been increased by up to three times, compared to a CO2 laser, and cutting non-ferrous metals such as copper, bronze is not a problem at all.State-of-the-art fibre laser technology is used by the world's largest manufacturers in industries such as automotive, shipbuilding, aerospace and wherever high performance with very high accuracy is required.

Fiber laser cuts more than just steel

In lasers of unknown origin the laser power is lost very quickly and after only one year they will no longer fulfil their purpose - so always buy from a reliable supplier

Faced with the economic challenges of 2023, Polish industrial entrepreneurs are facing a revolution in the financing of their businesses. The answer to these challenges is an innovative concept Factory Financewhich promises to transform the way we invest in CNC machines and cnc machine tools and other industrial equipment.

Factory Finance is a unique approach that combines equity, leasing and EU funds. It is hybrid financing that eliminates the lengthy procedures associated with EU grants, offering entrepreneurs flexibility and speed in their investment decisions.

Under this concept, companies submitting projects for an EU grant can already start ordering the necessary machinery and equipment at the application stage. This ground-breaking approach allows production processes to start immediately, which is crucial especially in a dynamic market environment.

First concept Factory Finance was born out of the genuine needs of entrepreneurs, who were trapped between the need to invest and the time to wait for a subsidy decision. Such a situation not only delayed the development of companies, but also hampered the Polish economy. Entrepreneurs were forced to halt their development while waiting for the CNC machines, milling plotters and other industrial support equipment.

Factory funding removes this barrier, enabling entrepreneurs to respond instantly to market demand. Thanks to shortened financing procedures, entrepreneurs receive funds immediately. This allows investment decisions to be made quickly and avoids lengthy waits for EU decisions.

Concept Factory Finance is the result of a collaboration between two experts: Przemysław Szymański, a specialist in the engineering industry, and Kamil Rojek, a specialist in financial markets. Their joint initiative has the potential to revolutionise the Polish industry.

Procedure Factory Finance is still being developed, but already offers entrepreneurs the chance for immediate growth, regardless of EU decisions. It is not only a financial measure, but also an incentive to invest, moving away from bureaucratic delays to faster growth.

Factory funding brings numerous benefits to Polish industry. Firstly, the shortened financing procedures eliminate the long delays associated with EU subsidies, enabling immediate action. Entrepreneurs gain not only time, but also the confidence to react quickly to changing market conditions.

Secondly, the hybrid financing model allows flexibility to adapt to different scenarios. In the event of receiving EU subsidyThe purchase will be financed with EU funds. In the event of a refusal, the entrepreneur can use own funds, a loan or leasing. This approach gives entrepreneurs more control over their investments.

Thirdly, Factory Financing is also an incentive for entrepreneurs to invest proactively. It offers an alternative to waiting a long time for grants, encouraging faster and more confident investment decisions.

The Factory Finance concept is a promising step into the future for Polish industry. As the procedures and model are developed, it is becoming a powerful tool to support the growth and development of companies.

If you think Factory Financing is the key to the development of Polish industry, and an effective way to encourage entrepreneurs to invest without unnecessary delays, please share your opinion with us.

This innovative concept can become a driving force for the development of the economy. It shortens the path to new technologies and increases the competitiveness of Polish companies on the global market.

We look forward to receiving your feedback and suggestions at the address:

finansowanie@maszyny-cnc.pl

We invite you to get acquainted with the offer of CNC Machines manufactured by the CNC Machine Factory

Developments in technology have had a huge impact on various areas of life, but particularly on industry. One area where changes are particularly evident is in the production and processing of metals, wood or plastics. CNC (Computer Numerical Control) machines are now indispensable tools in many industrial plants, allowing precise machining of different types of materials. However, the purchase of this type of machinery can be costly, so it is important to find appropriate sources of funding. In this blog post, we will discuss some key steps, and ways to finance CNC machine tools currently the most popular on the market to help you obtain financing for CNC machines.

Before deciding to finance CNC machinery, it is important to understand exactly what your needs are and the costs associated with the purchase, operation and maintenance of these machines. A detailed analysis will allow you to determine exactly how much financing you need, what real long-term revenue such a purchase can bring you.

It is also necessary to identify the operating and maintenance costs of CNC machines. This includes costs for energy, consumables, spare parts and maintenance. Also to be considered are the costs associated with maintenance, emergency repairs and regular inspections, which are key to keeping machines in optimum condition.

Another aspect is to understand what specific production needs will be served by the CNC machines. These determine the type and parameters of the machines to be purchased. You need to consider the type of materials you will be working with, the complexity of the parts to be made, the expected production rate and the level of precision required. The following are available on the market metalworking machines, woodworking machines, milling plotters for advertisingcnc cutting machines. You need to determine for yourself whether you want to buy a cnc machine dedicated to a particular industry or a specialised machine with the possibility of multifunctional operations (cnc milling, cnc cutting, engraving, milling for bends, etc...).

Another important element of the analysis is to determine the expected profits to be generated by the purchase of CNC machinery. This will estimate the potential return on investment in the long term. This analysis is crucial for convincing investors or financial institutions of the profitability and prospects associated with the machinery purchase.

He must also be vigilant and analyse the market and the competition. You need to understand what the industry standards are, and you need to choose such a cnc machine so that innovating further is not problematic. You need to take a forward-looking view of your production and its capabilities.

A thorough cost and needs analysis is the foundation for making wise investment decisions. It allows you to avoid unexpected costs, select the optimal technological solution and increase the efficiency and profitability of your business. It is a key part of the preparatory process prior to the purchase of CNC machinery that will contribute to the success of the investment.

Bank loans are currently the least popular option in terms of interest rates. However, it is always worth considering this option, as banking facilities often offer investment funding at preferential interest rates, often with support from the BGK. It is crucial to compare the offers of different banks in terms of interest rates, repayment period, availability of the loan and possible collateral required by the bank.

Leasing is one of the most popular investment financing options for the purchase of machinery

CNC and more. In the simplest terms, the principle of leasing is that a company rents machines from a leasing institution for a specific period of time after which it can buy the machines back. The longest leasing periods for cnc machines, CNC machine tools are 60 months. You can rent a CNC machine for 60 months and at the end of that period you can buy it outright. There are many leasing institutions on the Polish market offering this type of service. When signing the contract, an own contribution of 10% to 30% of the investment value is required.

This is an advantageous solution if you do not want to incur the full cost of the purchase at once, but want to pay instalments as you use the machines.

Cnc machines, cnc machine tools are most often financed through leasing. This is an extremely popular form of financing among small as well as large companies. It is also interesting to note that also STARTUPS with a 6-month business period, a good business plan and revenue can also apply for this type of financing. If you are considering purchasing a CNC machine via leasing, please contact us via the contact form - our advisor will present you with the best leasing options available on the market for our CNC machines.

The European Union offers a number of EU-funded support programmes, which can include grants for business development, innovation, modernisation or ecology. Entrepreneurs can use these funds for the purchase of machinery, CNC equipment under relevant competitions or programmes. The leader in announcing competitions increasing innovativeness of small and medium-sized enterprises is Polish Agency for Enterprise Development.

As part of the 2021-2027 subsidies you can find many interesting competitions to support development, innovation and investment in CNC equipment. Some examples below:

It offers funding to support innovative companies at all stages: from the idea, through research and development, to the market launch of the innovation.

Supporting your business in Eastern Poland - I offer to obtain EU support for research and investment, including the purchase of standard and multifunctional CNC machines.

This programme is intended for the provinces of Eastern Poland. Support is available to companies based in the Lubelskie, Podkarpackie, Podlaskie, Świętokrzyskie, Warmińsko-Mazurskie and Mazowieckie provinces, excluding Warsaw and its surrounding counties.

European funds for development and innovation are also available from the following intermediary bodies:

Regional Development Agencies: Local development agencies, marshal offices, or similar institutions in your region may offer grants for the development of enterprises, including investment in modern technologies, including CNC machines. It is worth keeping an eye on announcements and competitions organised by such agencies.

Government programmes: National governments often launch various types of business support programmes that include grants for investment in innovative technologies. Check the official websites of the ministries responsible for the economy, industry or innovation in your country.

Structural Funds: Structural funds are often used to support investment in industrial infrastructure, including the purchase of machinery and equipment. They can be managed at local, regional or national level.

Sector funds: Some sectoral organisations or chambers of commerce may offer grants for the development of businesses in their industry. Knowing these organisations and monitoring their announcements is key.

Innovation and research programmes: Programmes focused on innovation and research can offer financial support to companies investing in cutting-edge technology, including CNC machinery.

Remember that each funding source may have specific conditions and requirements for application and project implementation. It is important to carefully read the regulations and requirements of each programme and prepare complete and accurate application documentation.

Searching for angel investors

or Venture Capital (venture capital) funds can be an attractive option for entrepreneurs looking for funding. These investors may invest in your venture with the expectation of a return in the future. However, it is important to carefully define the terms of the investment and work out a mutually beneficial agreement.

Looking for favourable financing offers is a key step in the process of obtaining funding for the purchase of CNC machinery. The variety of options available allows you to tailor financing to suit your company's individual needs and capabilities. It's worth thoroughly researching each option, comparing offers and consulting experts to choose the most beneficial financing method. For the best cnc machines, cnc machine tools, milling plotters and cnc cutters, visit CNC Machine Tools Factories.

In recent times, developments in artificial intelligence and machine learning have contributed to significant advances in machining. CNC machines (Computer Numerical Control) are becoming increasingly sophisticated and advanced in terms of the artificial intelligence used in them. In this article, I will discuss some applications of artificial intelligence in CNC machines and their impact on the machining industry. Let's remember that soon milling plotters, cnc machine tools, cutting machines and other cnc machines will rely on artificial intelligence for most machining processes. Whether this is a good thing or a bad thing judge for yourself. See how artificial intelligence can make your work on CNC machines easier and faster.

The first application of artificial intelligence in CNC machines is the optimisation of machining processes. Artificial intelligence can be used to analyse machining processes in order to identify the optimal settings for machine parameters such as rotational speed spindles, feed speed and depth of cut. By analysing a range of machining process data, artificial intelligence can identify the best settings for a given material and shape. Milling plotters, cnc machines and cutting plotters, can achieve maximum productivity and minimise machining time.

A second application of artificial intelligence in CNC machines is to diagnose and prevent problems in the machines. CNC machines are complex machines and failures can be costly and time-consuming. Using artificial intelligence to analyse machine data allows for early detection and prevention of problems, which can significantly reduce the risk of failure and lost production time.

A third application of artificial intelligence in CNC machines is the optimisation of tool wear. Cutting tools are costly and require regular maintenance and replacement. Artificial intelligence can help optimise tool wear by analysing machine data and identifying optimal tool settings to maximise tool life and minimise tool replacement costs.

Conclusions

Artificial intelligence is becoming increasingly important in the machining industry and CNC machines are becoming more advanced through the use of this technology.

By using artificial intelligence, cnc machine tools can achieve greater productivity, reduce production costs and increase product quality. Optimising machining processes, diagnosing problems in machines and optimising tool wear are just some of the applications of artificial intelligence in CNC machines.

However, introducing artificial intelligence into CNC machines also requires a certain amount of knowledge and skill on the part of the operator. Operators need to be able to effectively use advanced artificial intelligence tools and algorithms to exploit the full potential of CNC machines. It is therefore important that employees receive adequate training in the operation of CNC machines using artificial intelligence.

In summary, the use of artificial intelligence in CNC machines has many benefits that positively impact the machining industry. Optimising machining processes, diagnosing problems in machines and optimising tool wear are just some of the applications of artificial intelligence in CNC machines. However, the introduction of artificial intelligence into CNC machines also requires proper training of operators so that they can effectively use these advanced technologies.

You realise that the world is moving forward, faster, more advanced than 10 years ago. New technologies are displacing old conventional solutions. You read, you check, you research the cnc machine market and you are almost ready to upgrade your machinery. For the purchase of that one CNC machine tool that will bring you money and production independence.

When considering the purchase of a cnc and spending hundreds of thousands of zlotys, you probably already have an idea of what you want to do on it. Nonetheless, think about it, analyse what kind of parts and assemblies you want to make on it.

You need to deconstruct your production so that the equipment you purchase is loaded to the maximum.

State-of-the-art CNC machine tools in addition to 2d, 3d milling, milling unitscan, with a rapid changeover to a suitable cutting unit oscillating cutting of cardboard, rubber, leather and a range of other materials).

Suitable CNC machine also has threading, creasing and scanning capabilities - which is why it is so important to know your needs. Some of the external costs can be passed on to your production thus burdening the equipment you purchase and generating further savings.

If you are planning simple cutting of a wide range of furniture, advertising and building panels, the machine you have in mind does not have to bear heavy loads - unless you plan on working three shifts. Suitable alternatives for this range of materials are milling plotters with the purpose of nesting. But remember that a wider range of materials may come into play in the future. If a customer wants a top made of the increasingly fashionable HPL board (a material characterised by very high hardness), you will not be able to carry out this order with a simple plotter.

Therefore, be considerate and think ahead. Don't limit yourself to the "here and now" when choosing your first machine. The consumer market is changing, it is fluid, the tastes of consumers are diverse, board manufacturers are also introducing product innovations. You must remember that only a versatile cnc machine will allow you to be competitive in the market and will not deprive you of new orders, the implementation of product innovations. No matter how turbulent the market is for consumers and manufacturers, you will always be one step ahead. For simple cuts, pay attention to the working, idle speeds of the machines - within reason, of course. Manufacturers, cnc suppliers often offer very high working speeds that are nowhere near the actual operation of CNC machines. The safe cutting speed is 500mm/s, idle speed up to 700m/s. With higher working parameters - there is a drastic wear of cutting tools, the purchase of which is the cost of running a CNC machine. Cutters wear out quickly and break down much faster. Tools are also your side cost of production and take this into account.

Yes, this question is fundamental - you may have dozens of enquiries for machining large-format moulds with an example size of 3000x6000mm but not enough space to locate the necessary cnc machine. You need to verify your plans with reality and recalculate the cost of profits and investment incurred.

Maybe you have small dimensions to work with and that's all your production is based on - then the obvious choice is to go small cnc milling and engraving machines. They are probably much cheaper than large-scale CNC machine tools - but you won't make specialised large-format moulds for composites on them.

When selecting even small milling machines, it is worth paying attention to the price and capabilities of the machine. Often machines from global manufacturers are offered at highly inflated prices with functionality similar to domestic manufacturers who offer machines at similar prices. You need to analyse the maximum dimensions of the workpieces and compare them with the location possibilities of your shop. The best way to do this is to use diagrams of the external dimensions of the CNC machines you are considering purchasing.

Initially, you will be comparing offers from different manufacturers and the most important aspect of your choice will be the price - this will initially play a major role in the purchasing process. If you want to acquire good and reliable equipment, let's not hide - it will not be a cheap purchase. You can, also trust the importers of Chinese machines. The quality of this equipment and the functionality is equal to the price. Don't be surprised if you soon regret this purchase.

Remember if you want to do serious production you need to choose a professional CNC machine tool. A CNC machine is not an investment for one or two years, so price and constant access to spare parts and service support from the machine manufacturer or distributor are extremely important aspects.

You must include professional training or employment of a CNC operator among the incidental costs of purchasing CNC equipment. Before taking delivery of the machine, supplier manufacturers provide basic training on the machine's control system, the basics of how to operate and explant the machine. You can invest in professional training or learn from your mistakes - empirically. The best option is to learn the new equipment yourself - this is basic, then train the right people. Even if an employee wants to change jobs you will be able to continue production on your own.

And one more important aspect - not every manufacturer invests in hundreds of thousands of zlotys in marketing and sales activities, some will focus a strike on the product and its functionality. Therefore, you need to set your radars against marketing 'gibberish' and sales gimmicks. The best step is to visit the manufacturer, talk to them directly and assess the capabilities of the CNC machine you are interested in.

Cnc machine tools and modern technology have undoubtedly been accompanying industry and entrepreneurship for several decades. As early as the mid-20th century, factories in the United States began to gradually introduce CNC machining technology in continuous production - to produce more, cheaper, more accurately and faster.

From the 1960s onwards, cnc technology was gradually introduced to the world market in small steps. Cnc machine tools have evolved in line with user demand. The cnc machines were becoming more advanced and tailored to individual needs - specific to particular industries.

Today cnc machine is not something new, it is a 'MUST HAVE' device in most production facilities, from carpentry to aviation and heavy industry.

Initially, entrepreneurs were afraid to invest in such advanced equipment. In Poland at that time, the digital transformation was just in its infancy. The daredevils who dared to invest in new technologies at that time - today they are probably already millionaires.

Today's market is governed by specific conditions. Economic and energy instability, fluctuations in market demand and supply, and a shortage of staff are the plight of many organisations. Having modern CNC machines allows you to re-brand your production to a completely different plant specification at any time. A perfect example was during the Covid-19 pandemic, where the economy came to a standstill in its early stages. Lucky were the owners of cnc cutters with oscillating heads. They started mass production of visors and this production was the main source of income and profit. They quickly adapted their plants to market demand and demand.

It was important to have the right idea and the right tools - the cnc machines, once set up, started a completely new production process.

Appropriate cnc machines give you production freedom independent of market conditions, allow you to develop your organisation, product, implement new concepts and production plans. The cnc machines in your plant mean savings in time, production materials, a significant reduction in labour costs compared to manual, artisanal work. In the era of the new industrial revolution of Industry 4.0, production automation is becoming a necessity. Large corporations as well as small and medium-sized entrepreneurs are aware of this. They are all increasingly willing to invest in new technologies, equipping their machine parks with modern cnc machine tools, cnc milling machines, engraving machines, cnc cutters.

Automation of production makes it possible for companies to be competitive in the market - to offer better quality goods, often at lower prices. Thanks to cnc machines, they can produce: faster, cheaper, change industrial designs, adapt to the market

Soon, owning cnc machines will be the standard for every manufacturing company. Without this equipment, production will be unprofitable.

If you need to select a CNC machine suitable for your production write to us. Our consultants will offer you the best solutions on the market.